Wholesale Continual Plate Dryer Equipment

Continual Plate Equipment Supplier And Manufactures--At hc-dryerequipment.com

Fob Price:USD18000~USD180000

Supply Ability:5 sets / month

Mini Quantity:1 set

Port:Shanghai Port

Payment Terms:T/T, L/C at sight

Size:Different size according to the machine

Material:Stainless steel, Carbon steel

Clients:□supplier ▲manufacturer ▲company ▲factory ▲distributor ▲agent ▲final user

Marketing Area: worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc

Continual Plate Dryer Equipment, Wholesale Various High Quality Continual Plate Dryer EquipmentProducts From hc-dryerequipment.com Continual Plate Dryer Equipment Suppliers and Continual Plate Dryer Equipment Factory.

Description:

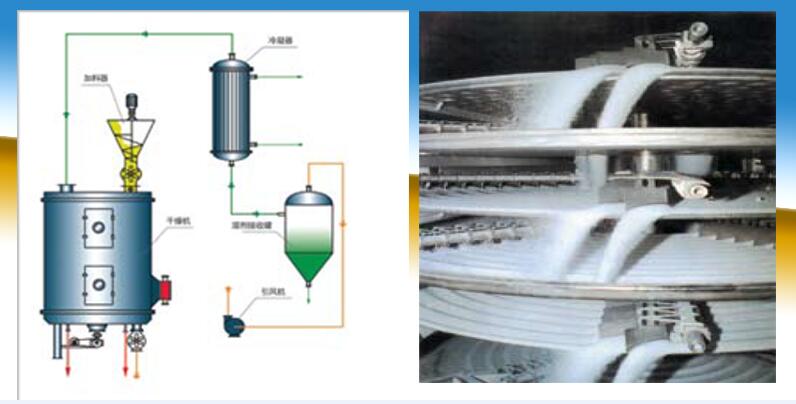

PLG series Continual Plate Dryer Equipment is a kind of high efficiency conducting and continuous drying equipment. Its unique structure and operating principle provide advantages of high heat efficiency, low energy consumption, less occupying area, simple configuration, easy operation and control as well as good operating environment etc. It is widely used in drying process in the fields of chemical, pharmaceuticals, agricultural chemicals, foodstuff, fodder, process of agricultural and by-products etc., and is well received by various industries. Now there are three big categories, normal pressure, closed and vacuum styles and four specifications of 1200, 1500, 2200 and 2500; and three kinds of constructions A (carbon steel), B (stainless steel for contact parts) and C (on the basis of B to add stainless steel for s team pipes, main shaft and support, and stainless steel linings for cylinder body and top cover).With a drying area of 4 to 180 square meters, now we have hundreds of models of series products and various kinds of auxiliary devices available to meet requirements of various products.

Work Principle:

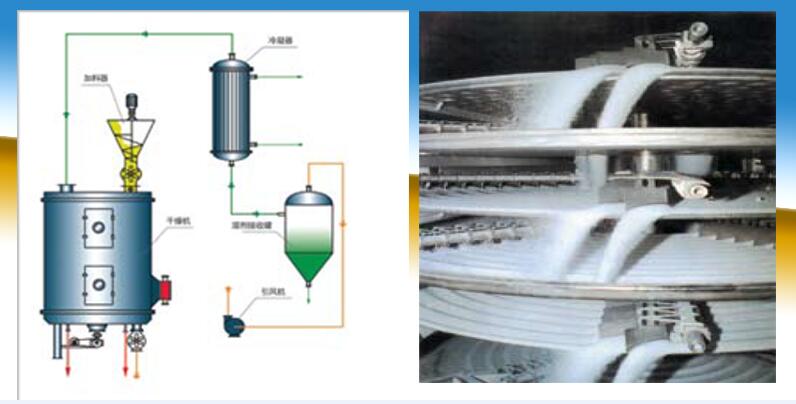

Wet materials are fed continuously to the top drying layer in the dryer. They will be turned and stirred continuously by harrows when the harrow’s arm rotates, the material flows through the surface of the drying plate along the exponential helical line. On the small drying plate the material will be moved to its exterior edge and drop down to the exterior edge of the large drying plate underneath, and will then be moved inward and drop down from its central hole to the small drying plate on the next layer. Both small and large drying plates are arranged alternately so as materials can go through the whole dryer continuously. The heating media, which could be saturated steam, hot water or thermal oil, will be led into hollow drying plates from one end to other end of the dryer. The dried product will drop from the last layer of the drying plate to the bottom layer of the smell body, and will be moved by harrows to the discharge port. The moisture exhausts from materials and will be removed from the moist discharge port on the top cover, or sucked out by the vacuum pump on the top cover for vacuum-type plate dryer. The dried product discharged from the bottom layer can be packed directly. The drying capability can be raised up if equipped with supplementary devices such as finned heater, condenser for solvent recovery, bag dust filter, return and mix mechanism for dried materials and suction fan etc. solvent in those paste state and heat sensitive materials can be easily recovered, and thermal decomposition and reaction can be also carried out.

Product Characteristics:

I. Easy regulation and control, strong adaptability

*Regulate thickness of materials, rotating speed of main shaft, number of harrow’s arm, style of and sizes harrows achieve best drying process.

*Each layer of drying plate can be fed with hot or cold media individually to heat or cold materials and make temperature control accurate and easy.

*Stay time of materials can be accurately adjusted.

*Single flowing direction of materials without return flowing and mixing, uniform drying and stable quality, no re-mixing is required.

II. Easy and simple operation

*Start and stop of dryer is quite simple

*After material feeding is stopped; they can be easily discharged out of the dryer by harrows.

*Careful cleaning and observation can be carried inside the equipment through large-scale viewing window.

III. Low energy consumption

*Thinner layer of materials, low speed of main shaft, small power and energy required for conveying system of materials.

*Drying by conducting heat so it has high heating efficiency and low energy consumption.

IV. Friendly environment, solvent can be retrieved and dust powder discharge can meet requirement.

*Normal pressure: as low speed of air flow inside the equipment and moisture being high in upper part and low in lower part, dust powder couldn’t float to the equipment, so there is almost no dust powder in tail gas discharged from the moist discharge port on the top.

*Close type: equipped with solvent recovery device that can recover organic solvent easily from moist-carrier gas. The solvent recovery device has simple structure and high recovery rate, and nitrogen can be used as moist-carrier gas in closed circulation for those subject to burning, explosion and oxidation, and poisonous materials in order for safe operation. Especially suitable for drying of flammable, explosive and poisonous materials.

*Vacuum style: if the plate dryer is operating under vacuum state, it is particularly suitable for drying heat sensitive materials.

V. Easy installation and small occupying area.

*As the dryer is in a whole for delivery, it is quite easy to install and fix at site only by hoisting.

*As drying plates being arranged by layers and installed vertically, it takes a small occupying area though drying area is large.

Material to be dried:

Organic chemicals * Mineral chemical s *Pharmaceutical and foodstuff * Feed and fertilizer.

Technical Parameter:

|

Jun-00

|

Φ3150

|

3319

|

26.3

|

4

|

|

Oct-00

|

4159

|

43.8

|

5.5

|

|

2500/14

|

4999

|

61.3

|

7.5

|

|

2500/18

|

5839

|

78.8

|

11

|

|

2500/22

|

6679

|

96.3

|

|

2500/24

|

7099

|

105

|

13

|

|

Aug-00

|

Φ3800

|

4050

|

48

|

11

|

|

Dec-00

|

5250

|

72

|

|

3000/18

|

7050

|

108

|

13

|

|

3000/26

|

9450

|

156

|

15

|

|

3000/28

|

10050

|

168

|

Steel plate cutting →Steel plate bending →Welding→ Drilling → Polishing →Assembling

For each process, we required our workers to control the quality strictly according to ISO 9001-2008 and Process technology, so that we can get the quality machine of Customer satisfaction

Shipping & Customer Site :

Our factory have more experience for shipping Continual Plate Dryer equipment by container, and guide installation and commissioning to customer local.

Our Continual Plate Dryer equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows:

Our Services:

24 hours online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free parts for any breakdown with convincing eviden

Our Advantages:

1. High quality and 20 years experience professional manufacturer of Continual Plate Dryer equipment

2. Our factory is certificated by BV,GMC,TUV SGS

3. Our factory is certified by ISO9001:2008 & ISO14001:2004

4. Short lead time

5. Good after-sale service

6. Overseas guide installation and commissioning

FAQ:

1. Are you manufacturer or trading company?

We are manufacturer 20 years experience professional manufacturer of dryer equipment,mixer equipment,granulator equipment.

2. Where is your factory located?

Our factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to our factory is

about 260Km,it need

about 3 hours by car.

3. If can make a testing in your factory?

Sure, our factory have Continual Plate Dryer equipment testing.

4. How Can I select the right Continual Plate Dryer equipment ?

We will help you choose the right type and model for Continual Plate Dryer equipment, by knowing the following information:

a.> Raw material name and property: Water contents, viscosity , surface tension, size and PH value.

b.> Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

c.> Output capacity: shift time daily .

d.> Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

e.> Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric compnent brand require.

f.> Powder collection requirement: whether it’s necessary to use cloth bag ilter and the requirement of the environment of the exhausted gas .

g.> Other special requirements.

Our Continual Plate Dryer equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows:

Our Continual Plate Dryer equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows: