Best Sale Fluid Bed Dryer Equipment

Fluid Bed Dryer Equipment Supplier And Manufactures--At hc-dryerequipment.com

Fob Price:USD9000~USD150000

Supply Ability:6 sets / month

Mini Quantity:1 set

Port:Shanghai Port

Payment Terms:T/T, L/C at sight

Size:Different size according to the machine

Material:Stainless steel, Carbon steel

Clients:□supplier▲manufacturer▲company▲factory ▲distributor ▲agent ▲final user

Marketing Area: worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc

Fluid Bed Dryer Equipment, Wholesale Various High Quality Fluid Bed Dryer Equipment Products From hc-dryerequipment.com Fluid Bed Dryer Equipment Suppliers and Fluid Bed Dryer Equipment Factory.

Description:

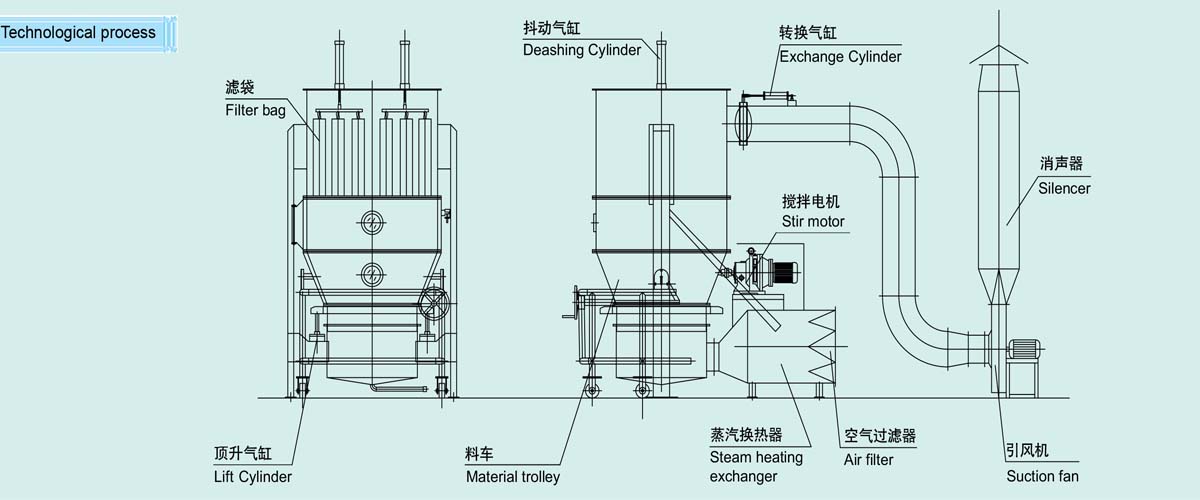

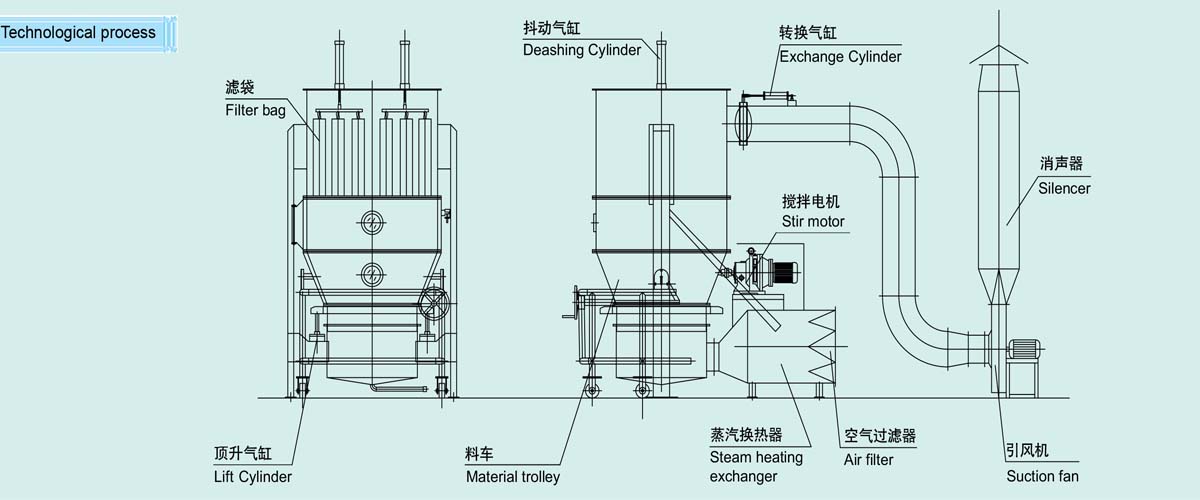

Fluid Bed Dryer is formed when a quantity of a solid particulate substance (usually present in a product container) is placed under appropriate conditions to cause the solid / binding agent mixture to behave as a fluid. This is usually achieved by the introduction of pressurized fluid through the particulate medium. These results in the product move up and down and disperse into the air between the filter bag housing and the product container. The resulting phenomenon is called fluidization. Fluidized beds are used for several purposes, such as simple Dryers, Granulation, coating etc.

After purifying and heating, the air flows through the distribution plate into the bed. The materials become fluidized by the effect of the air and the agitation. In large gas-solid phase contact, materials water evaporated rapidly, high-humidity air being sucked out the dryer, materials meet the dry requirements.

Product Characteristics:

♦The fluid bed is a circular structure, to avoid the dead angle, and make sure easy cleaning.

♦There is an agitator in the bed to prevent the reunion of moist materials and channeling in the drying process.

♦It uses over-dumping discharge system, convenient, rapidly, and completely. It can also be prepared with automatic feeding-discharging system as required.

♦It is fast drying, temperature uniformity, 15~30 minutes for each batch to dry in general.

♦It is sealed and working under negative pressure, designed according to GM P specification.

Material to be dried:

♦Inorganic: Sodium perchlorate, persulfate, sodium perforate, basic nickel carbonate.

♦Organic: Aminoguanidine bicarbonate, 1-chloroanthraquinone, tartaric acid, sodium tartaric, potassium tartrate, o-chlorobenzoic, thiadiazole.

♦Medicine: SD (sulfadiazine), sulfathiazole, clarithromycin, L-tryptophan, tetracycline, sulfadoxine.

♦Food and feed additives: Acesulfame potassium, feed Aureomycin, potassium sorbate, betaine.

♦Dyes: Red base, cationic golden yellow x-GL, cationic red x-G RL, action blue x-G RRL.

♦Pesticides: Chlorpyrifos, glyphosate, phosethyl-Al, tebuconazole, acephate.

♦Chemical Agents: Ferrocene, casein.

Application Range:

♦Applicable to the drying of powder, granular, sheet, column, and cake-like material, general size of 50 (300 mesh), 6000 (3 mesh) micron.

♦It is applied to screw extruder particles, rock particles, and high-speed mixing granulation particles.

♦It is applied to the drying of materials with strict requirements of final water content and dry temperature

Technical Parameter:

|

Item

|

Specification

|

|

Capacity

|

Kg

|

60

|

100

|

120

|

150

|

200

|

300

|

500

|

1000

|

|

Fan

|

Air Q’ty

|

M3/h

|

2361

|

3488

|

4000

|

4901

|

6032

|

7800

|

10800

|

15000

|

|

Air Pressure

|

mmH2O

|

594

|

533

|

533

|

679

|

787

|

950

|

950

|

1200

|

|

Power

|

Kw

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

45

|

75

|

|

Stirring Power

|

Kw

|

0.55

|

0.55

|

0.55

|

0.55

|

0.75

|

1.5

|

1.5

|

2.2

|

|

Stirring Speed

|

rpm

|

11

|

|

Consume of Steam

|

Kg/h

|

141

|

170

|

170

|

240

|

282

|

366

|

451

|

800

|

|

Time of Operation

|

min

|

15~30(depend on material)

|

|

Height of Main Machine

|

mm

|

2700

|

2900

|

2900

|

2900

|

3300

|

3800

|

4200

|

5800

|

Steel plate cutting →Steel plate bending →Welding→ Drilling → Polishing →Assembling

For each process, we required our workers to control the quality strictly according to ISO 9001-2008 and Process technology, so that we can get the quality machine of Customer satisfaction.

Shipping & Customer Site :

Our factory have more experience for shipping Fluid Bed dryer equipment by container, and guide installation and commissioning to customer local.

Our Fluid Bed dryer equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows:

Our Services:

24 hours online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free parts for any breakdown with convincing eviden

Our Advantages:

1. High quality and 20 years experience professional manufacturer of Fluid Bed dryer equipment

2. Our factory is certificated by BV,GMC,TUV SGS

3. Our factory is certified by ISO9001:2008 & ISO14001:2004

4. Short lead time

5. Good after-sale service

6. Overseas guide installation and commissioning

FAQ:

1. Are you manufacturer or trading company?

We are manufacturer 20 years experience professional manufacturer of dryer equipment,mixer equipment,granulator equipment.

2. Where is your factory located?

Our factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to our factory is

about 260Km,it need

about 3 hours by car.

3. If can make a testing in your factory?

Sure,our factory have Fluid Bed dryer equipment for testing, you can take 10~20kgs raw material to our factory for testing.

4. How Can I select the right Fluid Bed dryer equipment ?

We will help you choose the right type and model for Fluid Bed dryer equipment, by knowing the following information:

a.> Raw material name and property: Water contents, viscosity , surface tension,size and PH value.

b.> Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

c.> Output capacity: shift time daily .

d.> Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

e.> Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric compnent brand require.

f.> Other special requirements.