|

Item |

KJG3 |

KJG9 |

KJG13 |

KJG18 |

KJG29 |

KJG41 |

KJG52 |

KJG68 |

KJG81 |

KJG95 |

KJG110 |

|

Spec |

|||||||||||

|

Heat transferring area(m2) |

3 |

9 |

13 |

18 |

29 |

41 |

52 |

68 |

81 |

95 |

110 |

|

Effective volume(m3) |

0.06 |

0.32 |

0.59 |

1.09 |

1.85 |

2.8 |

3.96 |

5.21 |

6.43 |

8.07 |

9.46 |

|

Range of rotating speed(rmp) |

15-30 |

10~25 |

10~25 |

10~20 |

10~20 |

10~20 |

10~20 |

10~20 |

5~15 |

5~15 |

5~10 |

|

Power(kw) |

2.2 |

4 |

5.5 |

7.5 |

11 |

15 |

30 |

45 |

55 |

75 |

95 |

|

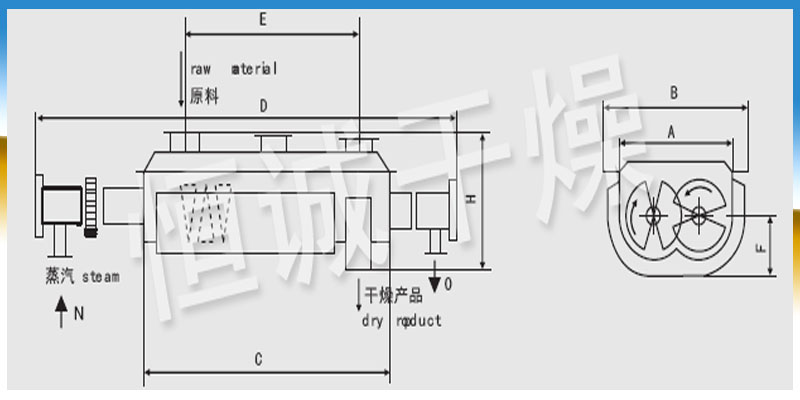

Width of vessel(mm) |

306 |

584 |

762 |

940 |

1118 |

1296 |

1476 |

1652 |

1828 |

2032 |

2210 |

|

Total width(mm) |

736 |

841 |

1066 |

1320 |

1474 |

1676 |

1854 |

2134 |

1186 |

2438 |

2668 |

|

Length of vessel(mm) |

1956 |

2820 |

3048 |

3328 |

4114 |

4724 |

5258 |

5842 |

6020 |

6124 |

6122 |

|

Total length(mm) |

2972 |

4876 |

5486 |

5918 |

6808 |

7570 |

8306 |

9296 |

9678 |

9704 |

9880 |

|

Distance of material inlet& outlet(mm) |

1752 |

2540 |

2768 |

3048 |

3810 |

4420 |

4954 |

5384 |

5562 |

5664 |

5664 |

|

Height of center(mm) |

380 |

380 |

534 |

610 |

762 |

915 |

1066 |

1220 |

1220 |

1220 |

1220 |

|

Total height(mm) |

762 |

838 |

1092 |

1270 |

1524 |

1778 |

2032 |

2362 |

2464 |

2566 |

2668 |

|

Steam inlet(inch) |

3/4 |

3/4 |

1 |

1 |

1 |

1 |

1 1/2 |

1 1/2 |

1 1/2 |

1 1/2 |

2 |

|

Water outlet(inch) |

3/4 |

3/4 |

1 |

1 |

1 |

1 |

1 1/2 |

1 1/2 |

1 1/2 |

1 1/2 |

2 |