Spray Dryer Equipment for distributor

Spray Dryer Equipment Supplier And Manufactures--At hc-dryerequipment.com

Fob Price:USD9000~USD300000

Supply Ability:5 sets / month

Mini Quantity:1 set

Port:Shanghai Port

Payment Terms:T/T, L/C at sight

Size:Different size according to the machine

Material:Stainless steel, Carbon steel

Clients:□supplier ▲manufacturer ▲company ▲factory ▲distributor ▲agent ▲final user

Marketing Area: worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc

Spray Dryer Equipment, Wholesale Various High Quality Spray Dryer Equipment Products From hc-dryerequipment.com Spray Dryer Equipment Suppliers and Spray Dryer Equipment Factory.

Description:Spray drying is the technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is most suitable for producing solid powder or particle products from liquid materials, such as: solution, emulsion, suspension and pumpable paste states ,For this reason, when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

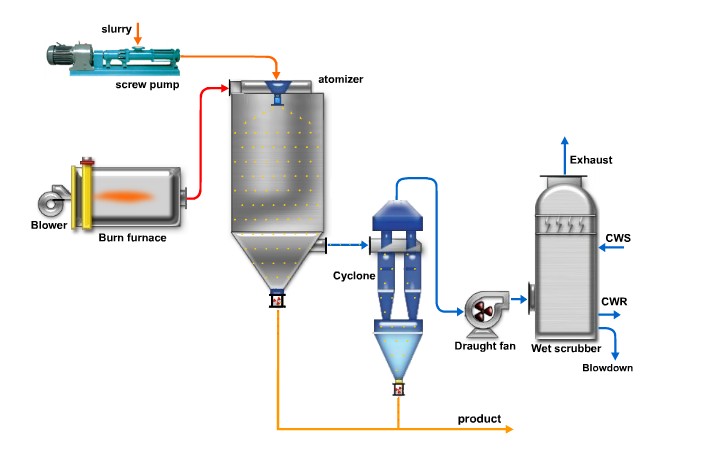

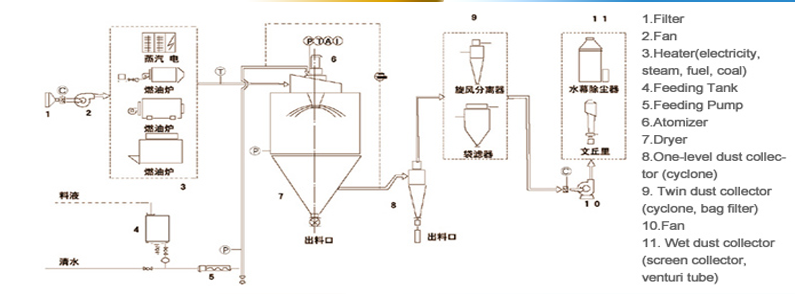

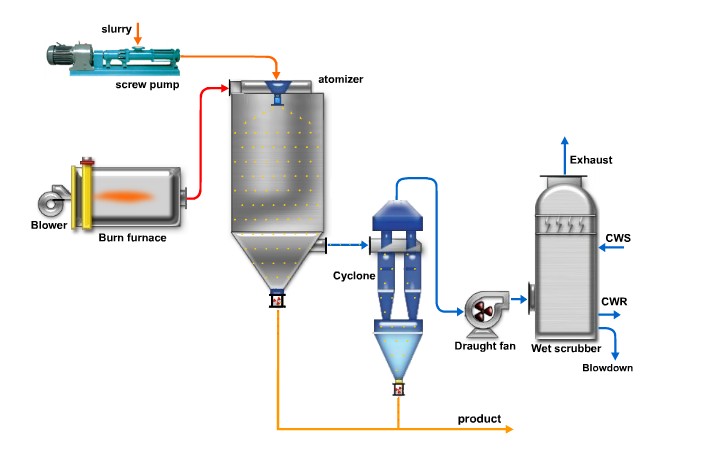

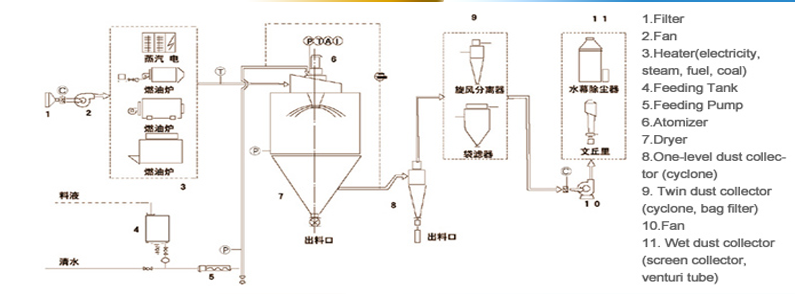

Work Principle:

High Speed Centrifugal Spray Dryer Equipment Series of LPG is gas-liquid co-current flow drying equipment, using high-speed centrifugal atomizer, the liquid will be atomized into fine droplets, then mix with the hot air from the distributor in the dryer, heat and mass transfer exchanges rapidly during the mixing process. In a very short period of time the liquid become dry powdered products. Production control and product quality control is convenient and reliable. It is widely used in the drying production of different types of liquids materials.

Product Characteristics:

Product Characteristics:

◆Different types of solution, suspension, emulsion and cream paste material can be dry for a one-time production.

◆The fog moment and fog droplet of spray-drying can be slightly adjusted.

◆The hot air has been reasonable allocation, and the ceiling and walls sticky situation has been eliminated.

◆It is suitable for the drying of thermo-sensitive and non thermo-sensitive material at the same time. The product particles are smaller than pressure spray dryer.

◆Simplify the production process, easy to use, good liquidity and instant of the product.

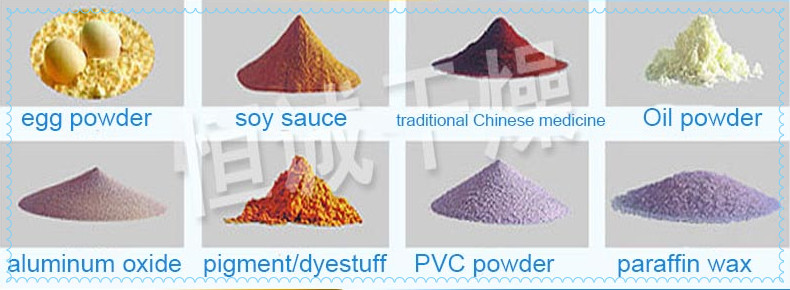

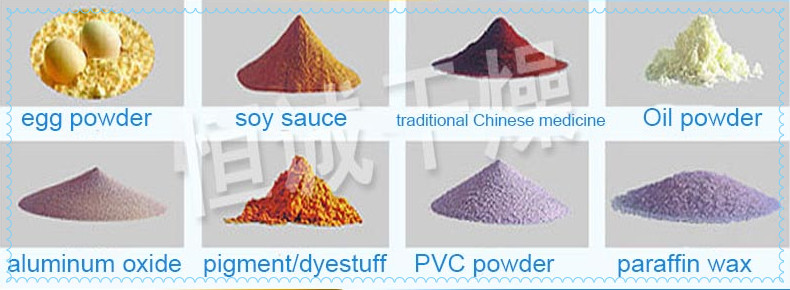

Material to be dried(Application):

For a variety of chemical, food, pharmaceutical and other industries liquid materials(as follows) dried into powder

For a variety of chemical, food, pharmaceutical and other industries liquid materials(as follows) dried into powder

◆Inorganic: aluminum nitride, zirconia, potassium fluoride, bentonite, kaolin, barium sulfate, lead sulfate, sodium aluminum, chromium oxide, titanium dioxide.

◆Macromolecule polymers: urea-formaldehyde resin, PVC.

◆Dyes: dispersol red FB, reactive dyes, etc.

◆Chemical Agents: silica dioxide, diatomite, sodium silicate, wood calcium, sodium ligninsulfonate, naphthalene series water reducer.

◆Pesticide: carbendazol chloride wettable power.

◆Food and feed additives: casein peptide phosphate, potassium sorbate, fish serum.

◆Fertilizer: potassium humate, sodium humate.

Technical Parameter:

|

Model

|

Max water evaporation(kg/h)

|

Inlet

Air tem(℃)

|

Outlet air tem(℃)

|

Transmission Model for atomizer

|

Rotate speed

(rpm)

|

Spray disk diameter

(mm)

|

Dimension

(L ×W× H)

(m)

|

|

LPG5

|

5

|

140-350 (auto control)

|

80-90

|

Compress Air

|

25000

|

50

|

1.8×0.9×2.2

|

|

LPG25

|

25

|

Mechanical

|

18000

|

120

|

3×2.7×4.3

|

|

LPG50

|

50

|

18000

|

120

|

3.3×3.2×5.1

|

|

LPG100

|

100

|

18000

|

120

|

4.6×4.2×7

|

|

LPG150

|

150

|

15000

|

150

|

5.5×4.5×7

|

|

LPG200-

|

200-2000

|

8000-15000

|

180-340

|

According to condition

|

|

2000

|

|

Note: There is relationship between the water evaporation, material characteristics and inlet air temperature

|

Steel plate cutting →Steel plate bending →Welding→ Drilling → Polishing →Assembling

For each process, we required our workers to control the quality strictly according to ISO 9001-2008 and Process technology, so that we can get the quality machine of Customer satisfaction

Shipping & Customer Site:

Our factory have more experience for shipping big spray dryer equipment by frame container, and guide installation and commissioning to customer local.

Our Spray dryer equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows:

Our Services:

24 hours online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free parts for any breakdown with convincing eviden

Our Advantages:

1. High quality and 20 years experience professional manufacturer of Spray dryer equipment

2. Our factory is certificated by BV,GMC,TUV SGS

3. Our factory is certified by ISO9001:2008 & ISO14001:2004

4. Short lead time

5. Good after-sale service

6. Overseas guide installation and commissioning

FAQ:

1. Are you manufacturer or trading company?

We are manufacturer 20 years experience professional manufacturer of dryer equipment,mixer equipment,granulator equipment.

2. Where is your factory located?

Our factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to our factory is

about 260Km,it need

about 3 hours by car.

3. If can make a testing in your factory?

Sure,our factory have Spray dryer equipment for testing, you can take 5~10kgs raw material to our factory for testing.

4. How Can I select the right Spray dryer equipment ?

We will help you choose the right type and model for Spray dryer equipment, by knowing the following information:

a.> Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

b.> Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

c.> Output capacity: shift time daily .

d.> Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

e.> Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric compnent brand require.

f.> Powder collection requirement: whether it’s necessary to use cloth bag ilter and the requirement of the environment of the exhausted gas .

g.> Other special requirements.