Roll Compactor Granulator Equipment

Roll Compactor Granulator Equipment Supplier And Manufactures- At hc-dryerequipment.com

Fob Price:USD8000~USD80000

Supply Ability:5 sets / month

Mini Quantity:1 set

Port:Shanghai Port

Payment Terms:T/T, L/C at sight

Size:Different size according to the machine

Material:Stainless steel, Carbon steel

Clients:□supplier ▲manufacturer ▲company ▲factory ▲distributor ▲agent ▲final user

Marketing Area: worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc

Roll Compactor Granulator Equipment, Wholesale Various High Quality Roll Compactor Granulator Equipment Products From hc-dryerequipment.com Roll Compactor Granulator Equipment Suppliers and Roll Compactor Granulator Equipment Factory.

Description:

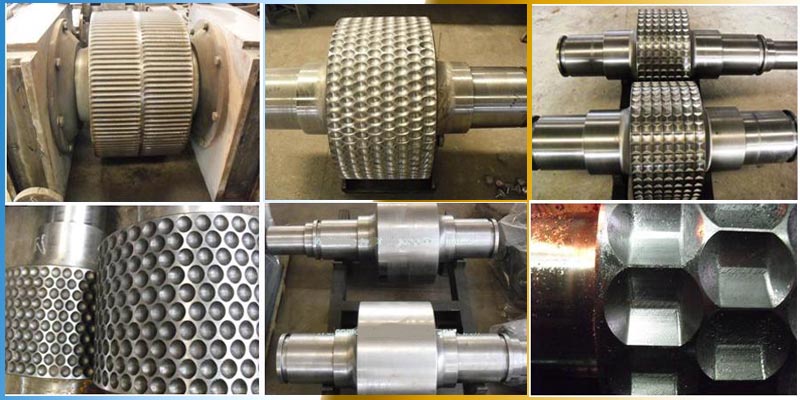

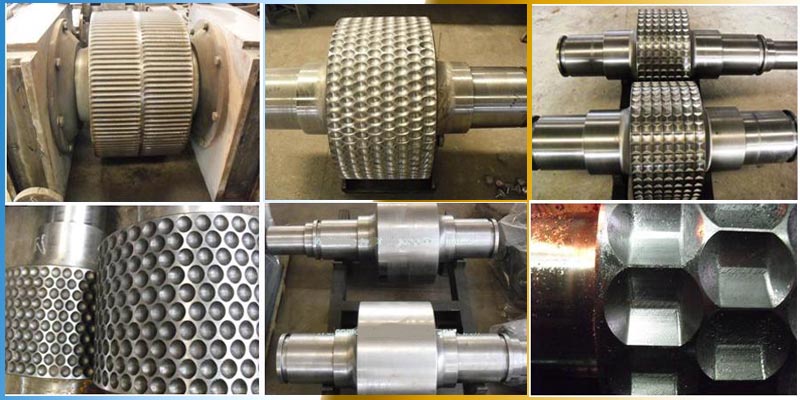

absorbed foreign advanced technique of powder granulator, improved and heightened on the basis of foreign technique, this Roll Compactor Granulator Equipment is developed by our factory. It has more reasonable and compact structure, simply technological processes, easy operation and better performance. Powder materials can be made into even granules customer needs without adding any bonding agent when they run through the machine. As density of granules are larger, no any afterward process is needed so as to reduce technological process, reduce granulation cost and powder pollution and improve labor environment as well.

Work Principle:

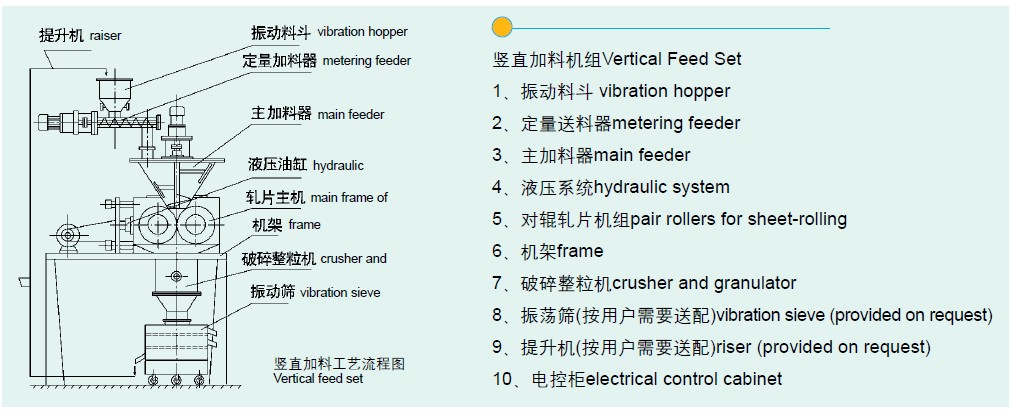

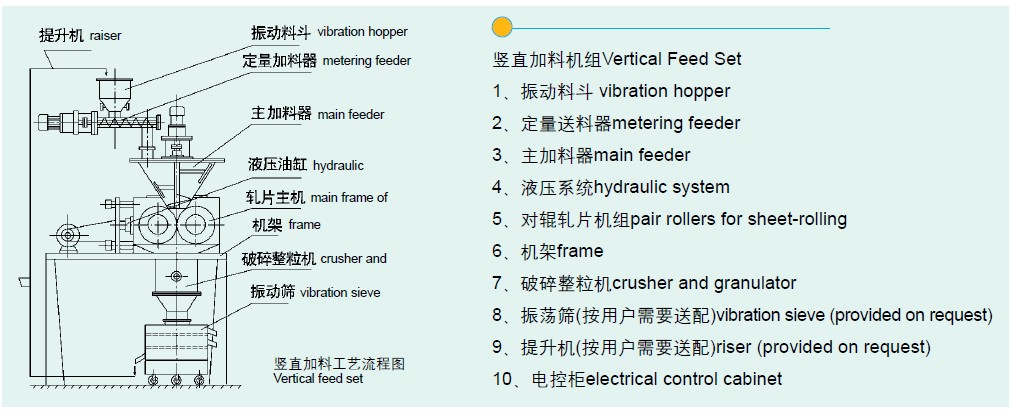

Vertical Feed Set After weight measured powder materials are sent laterally by the vibration hopper to the main feeder, deaerated by the stirring screw of the main feeder, pre-pressed and pushed into the arc grooves of left and right rollers. Driven by a pair of meshed gears, two rollers rotate in opposite direction with same speed, and powder materials are pressed into dense sheet while they run through rollers. Under the function of elastic recovery after rollers, they'll be separated from rollers and drop down, and fewer sheet not dropped will be scrapped off by the blade. Stripe grooves evenly distributed on the surface of rollers can prevent sliding when powder materials are fed into rollers. After crushed and granulated, they'll pass through the vibration sieve to be graded, and granules which meet requirement can be obtained. Powder after the sieve will return to the vibration hopper to be granulated circularly.

Product Characteristics:

1. Making granules from dry powder directly without any bonding agent.

2. The strength of granule can be adjusted by pressure of rollers so as to control strength of granule.

3. Sand-shaped irregular granules are produced.

4. Large productive capability due to continuous production. High degree of automation to suit automatic production.

Application:

Except those dangerous materials that are subject to explosion due to crushing and rubbing, most part of dry power materials can be directly granulated by this machine. If water-cooling is adopted for rollers by turning connectors, this machine can also be suited for granulation of heat sensitive materials.

Technical Parameter:

|

Item

|

Type

|

|

GL240-80

|

GL240-160

|

GL300-250

|

GL360-300

|

GL450-350

|

|

Diameter of roll (mm)

|

Φ240

|

Φ240

|

Φ300

|

Φ360

|

Φ450

|

|

Width of roll (mm)

|

80

|

160

|

250

|

200

|

350

|

|

Max pressure of roll (t)

|

50

|

60

|

80

|

100

|

130

|

|

Revolution of roll (rpm)

|

8~20

|

8~20

|

8~20

|

8~20

|

8~20

|

|

Max thickness of roll (mm)

|

4

|

5

|

6

|

8

|

8

|

|

Capacity of pressed pill (kg/h)

|

250-500

|

500-900

|

700-2000

|

1000-4000

|

2000-7400

|

|

Productive capacity (kg/h)

|

80-150

|

150-300

|

300-600

|

600-1000

|

1000-2000

|

|

diameter of finished products (mm)

|

0.2-5

|

0.2-5

|

0.2-8

|

0.2-8

|

0.2-8

|

|

Main motor power (kw)

|

7.5

|

11

|

18.5

|

30

|

45

|

|

Total power (kw)

|

11.5

|

17

|

28

|

43

|

60

|

|

Overall dimension (mm)

|

1500×1800×

3500

|

1500×2000×

3800

|

1800×2000×

4000

|

2000×2200×

4200

|

2200×2500×

4500

|

|

Weight (t)

|

5

|

6

|

8

|

10

|

13

|

Steel plate cutting →Steel plate bending →Welding→ Drilling → Polishing →Assembling

For each process, we required our workers to control the quality strictly according to ISO 9001-2008 and Process technology, so that we can get the quality machine of Customer satisfaction

Shipping & Customer Site :

Our factory have more experience for shipping Roll Compactor Granulator equipment by container, and guide installation and commissioning to customer local.

Our Roll Compactor Granulator equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows:

Our Services:

24 hours online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free parts for any breakdown with convincing eviden

Our Advantages:

1. High quality and 20 years experience professional manufacturer of Roll Compactor Granulator equipment

2. Our factory is certificated by BV,GMC,TUV SGS

3. Our factory is certified by ISO9001:2008 & ISO14001:2004

4. Short lead time

5. Good after-sale service

6. Overseas guide installation and commissioning

FAQ:

1. Are you manufacturer or trading company?

We are manufacturer 20 years experience professional manufacturer of dryer equipment,mixer equipment,granulator equipment.

2. Where is your factory located?

Our factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to our factory is

about 260Km,it need

about 3 hours by car.

3. If can make a testing in your factory?

Sure,our factory have Roll Compactor Granulator equipment for testing, you can take raw material to our factory for testing.

4. How Can I select the right Roll Compactor Granulator equipment ?

We will help you choose the right type and model for Roll Compactor Granulator equipment, by knowing the following information:

a.> Raw material name and property: Water contents, viscosity , surface tension,size and PH value.

b.> Dried granules density residual water contents allowed, particle size, and maximum temperature allowed.

c.> Output capacity: shift time daily .

d.> Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

e.> Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric compnent brand require.

f.> Other special requirements.