Round Ball Granulator Equipment price list

Round Ball Granulator Equipment Supplier And Manufactures--At hc-dryerequipment.com

Fob Price:USD7000~USD60000

Supply Ability:8 sets / month

Mini Quantity:1 set

Port:Shanghai Port

Payment Terms:T/T, L/C at sight

Size:Different size according to the machine

Material:Stainless steel, Carbon steel

Features:

1. Produce pellet size between 0.5~2.0mm

2. Process long granule becomes pellet.

3. Simple operation & effective operation time

Applications:

Clients:□supplier ▲manufacturer ▲company ▲factory ▲distributor ▲agent ▲final user

Marketing Area: worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc

Round Ball Granulator Equipment, Wholesale Various High Quality Round Ball Granulator Equipment Products From hc-dryerequipment.com Round Ball Granulator Equipment Suppliers and Round Ball Granulator Equipment Factory.

Application:

With the special design of rotor structure, the machine makes various wet grains into the perfect ball shape pellets. It is the desired equipment for making the capsules and pills of traditional Chinese medicine.

1. Pharmaceutical, Food Industries

2. Cosmetic, Dyestuff, Coloring Industries 3. Ceramic Industry

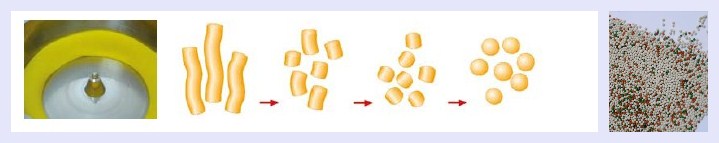

Working Principles:

Round Ball Granulator Equipment makes damp granule into beautiful pellet by setting rotating centrifugal disk, blower, and pneumatic nozzle. Feed damp granule into rotating centrifugal disk, start fan then start rotating centrifugal disk. It can make the damp granule in float and circle by the air from gap, rotating centrifugal strength and itself gravity, appear circle rope-turning movement and become high-degree ball shape pellet.

Technical Parameters:

|

spec

|

Ø230

|

Ø400

|

Ø700

|

Ø1000

|

|

power(Kw)

|

0.75

|

2.2

|

3.7

|

5.5

|

|

capacity(kg/h)

|

10-100

|

20-150

|

30-200

|

40-300

|

Steel plate cutting →Steel plate bending →Welding→ Drilling → Polishing →Assembling

For each process, we required our workers to control the quality strictly according to ISO 9001-2008 and Process technology, so that we can get the quality machine of Customer satisfaction

Shipping & Customer Site:

Our factory have more experience for shipping Round Ball Granulator equipment by container, and guide installation and commissioning to customer local.

Our Round Ball Granulator equipment have exported to worldwide, especially in Indonesia, Malaysia, Thailand, India, Iran, Syria, Saudi Arab, Korea, Russia, Uzbekistan, South Africa, Australia, New Zealand, Mexico, Columbia, Chile, Paraguay, Brazil, Argentina, Czech, Holland, and etc. Our main customer as follows:

Our Services:

24 hours online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free parts for any breakdown with convincing eviden

Our Advantages:

1. High quality and 20 years experience professional manufacturer of Round Ball Granulator equipment

2. Our factory is certificated by BV,GMC,TUV SGS

3. Our factory is certified by ISO9001:2008 & ISO14001:2004

4. Short lead time

5. Good after-sale service

6. Overseas guide installation and commissioning

FAQ:

1. Are you manufacturer or trading company?

We are manufacturer 20 years experience professional manufacturer of dryer equipment,mixer equipment,granulator equipment.

2. Where is your factory located?

Our factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to our factory is

about 260Km,it need

about 3 hours by car.

3. If can make a testing in your factory?

Sure,our factory have Round Ball Granulator equipment for testing, you can take raw material to our factory for testing.

4. How Can I select the right Round Ball Granulator equipment ?

We will help you choose the right type and model for Round Ball Granulator equipment, by knowing the following information:

a.> Raw material name and property: Water contents, viscosity , surface tension,size and PH value.

b.> Dried granules density residual water contents allowed, particle size, and maximum temperature allowed.

c.> Output capacity: shift time daily .

d.> Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oiland natural gas .

e.> Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric compnent brand require.

f.> Other special requirements.