|

Model No. |

Total volume |

feed rate |

feed weight |

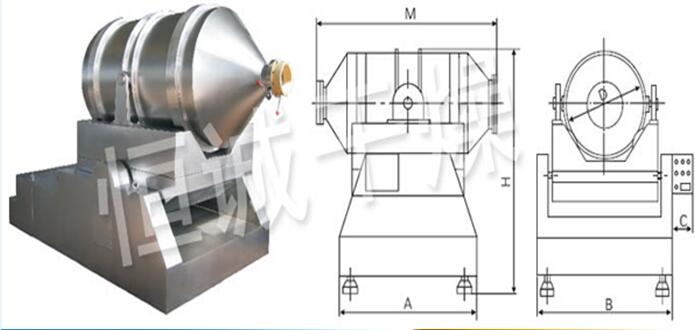

overall dimensions(mm) |

power(kw) |

||||||

|

(L) |

(kg) |

A |

B |

C |

D |

M |

H |

rotation |

sway |

||

|

EYH100 |

100 |

0.5 |

40 |

860 |

900 |

200 |

400 |

1000 |

1500 |

1.1 |

0.75 |

|

EYH300 |

300 |

0.5 |

75 |

1000 |

1100 |

200 |

580 |

1400 |

1650 |

1.1 |

0.75 |

|

EYH600 |

600 |

0.5 |

150 |

1300 |

1250 |

240 |

720 |

1800 |

1850 |

1.5 |

1.1 |

|

EYH800 |

800 |

0.5 |

200 |

1400 |

1350 |

240 |

810 |

1970 |

2100 |

1.5 |

1.1 |

|

EYH1000 |

1000 |

0.5 |

350 |

1500 |

1390 |

240 |

850 |

2040 |

2180 |

2.2 |

1.5 |

|

EYH1500 |

1500 |

0.5 |

550 |

1800 |

1550 |

240 |

980 |

2340 |

2280 |

3 |

1.5 |

|

EYH2000 |

2000 |

0.5 |

750 |

2000 |

1670 |

240 |

1100 |

2540 |

2440 |

3 |

2.2 |

|

EYH2500 |

2500 |

0.5 |

950 |

2200 |

1850 |

240 |

1160 |

2760 |

2600 |

4 |

2.2 |

|

EYH3000 |

3000 |

0.5 |

1100 |

2400 |

1910 |

280 |

1220 |

2960 |

2640 |

5 |

4 |

|

EYH5000 |

5000 |

0.5 |

1800 |

2700 |

2290 |

300 |

1440 |

3530 |

3000 |

7.5 |

5.5 |

|

EYH10000 |

10000 |

0.5 |

3000 |

3200 |

2700 |

360 |

1800 |

4240 |

4000 |

15 |

11 |

|

EYH12000 |

12000 |

0.5 |

4000 |

3400 |

2800 |

360 |

1910 |

4860 |

4200 |

15 |

11 |

|

EYH15000 |

15000 |

0.5 |

5000 |

3500 |

3000 |

360 |

2100 |

5000 |

4400 |

18.5 |

15 |